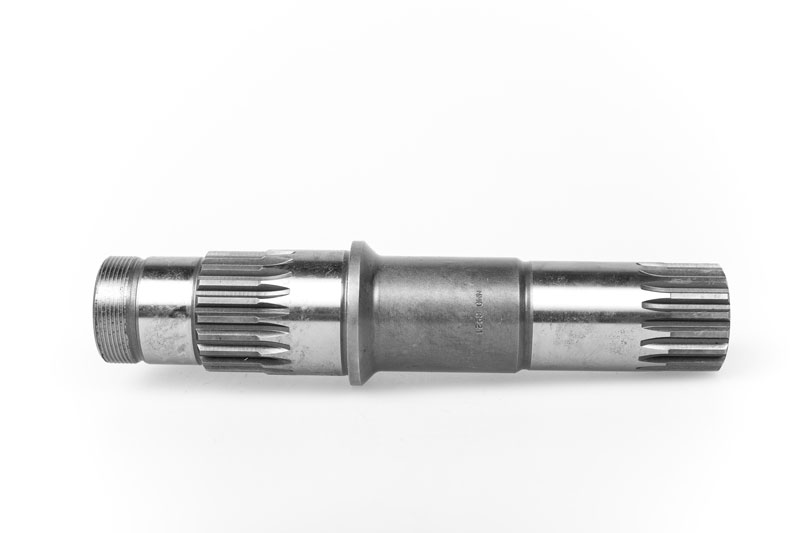

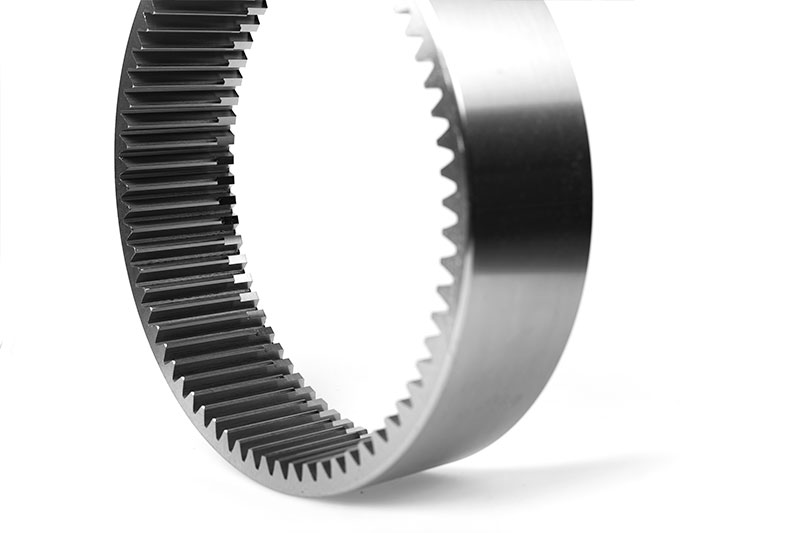

Montek cylindrical teeth gears

In the cylindrical gearing department, the most ambitious goal is the design and production of components that guarantee unrivalled stability, with attention to the smallest details and aimed at improving safety and practicality.

Our cylindrical gear department consists of machining units, some of which are CNC-controlled and have a loader.

We continue our professional and commercial growth by constantly investing resources in upgrading our production machinery to adapt to the changing market.

Specifically, we have:

| Module | Dimensions |

| from module 1.25 to module 6.5 | from Ø 50 mm to Ø 300 mm |

In order to be able to respond promptly to requirements (within size limits) and offer you an even better service, we have made the decision to use single-brand gear hobbing machines manufactured by a leading company.

On request, we also organise shipment to your premises and you can choose between full delivery and toll manufacturing.

The advantages of cylindrical gears

The efficiency of straight teeth cylindrical gears can reach values of over 99% with respect to reliability, they are robust and offer interchangeability even years later.

The application areas of spur gears

Our spur gears serve a variety of sectors and applications of the same can be used for: